Comparing Excavator Grapple Attachments

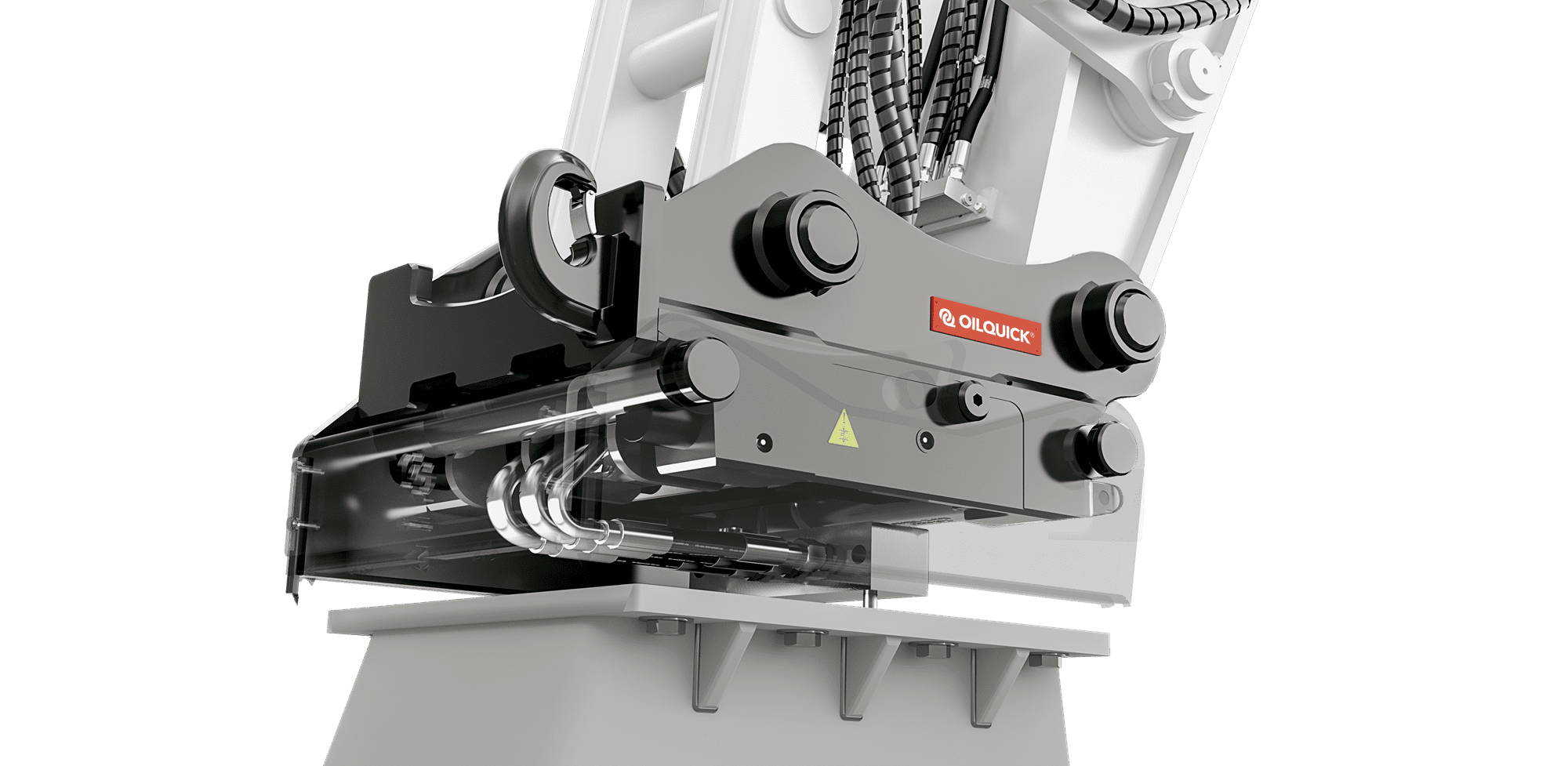

Unveiling the Power of Grab and Grapple Attachments for Excavators Excavators have long been hailed as the workhorses of construction sites and heavy-duty projects. Their versatility and raw power make them indispensable for tasks ranging from digging and trenching to material handling and demolition. But what truly elevates their capabilities to the next level are grab and grapple attachments. These attachments unlock a new dimension of efficiency and precision by providing excavators with the ability to grasp, hold, and manipulate various materials with ease. In this comprehensive article, we will delve into the world of grab and grapple attachments for excavators, exploring their types, applications, and the distinctions between fixed and rotation models Understanding Grab and Grapple Attachments Grab and grapple attachments are hydraulic-powered tools designed to transform excavators into versatile material handling machines. They allow excavators to grab and hold objects securely, making it possible to perform tasks that would otherwise be labor-intensive or impossible. From debris removal to forestry work and recycling operations, these attachments enhance the excavator’s functionality across a wide spectrum of applications. Grab/Grapple Applications Demolition: These heavy-duty attachments are specifically designed for demolishing structures and handling construction debris. Their robust construction and powerful grip enable them to pick up and maneuver heavy pieces of concrete, metal, and other debris with precision. Wood and Logging: For forestry and logging operations, wood and log grapples are essential. These attachments are equipped with specialized arms and gripping mechanisms that securely hold logs and timber, allowing for efficient loading, unloading, and stacking. Recycling: Recycling facilities rely on excavator recycling grapples to handle materials like scrap metal, plastics, and other recyclable items. These grapples are designed to withstand the rigors of handling sharp or irregularly shaped objects, making them a key player in sustainable waste management. Multi-Purpose: Multi-purpose grabs are engineered to handle a variety of materials and tasks. Their versatility makes them suitable for applications ranging from general material handling to sorting and separating different types of materials. These different grapple types all use the same principle; they just differ in design type and application. Mechanical vs Hydraulic & Fixed vs Rotating The distinction between fixed and rotation models lies in their ability to rotate or swivel the attached grab or grapple. Each model comes with its own set of advantages and considerations. Mechanical Models There are two types of fixed grapple attachments. The first and most basic version is shown below. One half of the grapple is mounted like a bucket and the other is fixed to the inside of the excavator’s stick like a thumb attachment. This can be fixed or hydraulic to allow the operator to control both sides of the grapple. This is the oldest version of a grab attachment and is generally the cheapest option. Advantages: Great for heavy duty applications where precision is not a major concern Simplified design, resulting in lower maintenance requirements. Generally more affordable than the other options Considerations: Limited flexibility when it comes to manipulating materials around obstacles or in tight spaces. May require more repositioning of the entire excavator to achieve the desired placement. Not easy to remove and use other attachments Hydraulic Models Hydraulic grabs use the auxiliary hydraulic circuit on the machine to open and close the grapple jaws whereas the mechanical grab above uses the bucket cylinder open/close to pick up the material. Using the auxiliary hydraulics of the machine gives the operator much more control and flexibility when using the attachment. These types of grabs can be used in many more applications and can also be fixed or rotating. Fixed A fixed hydraulic grab would be fixed in terms of rotation. Usually it would be mounted perpendicular to the machine to enable the operator to pick up large material without hitting the machine. However the mount could often be bolted to another fixed position that the operator prefers for the job at hand. Mounts can also be built with a multi pick up system. If the machine has a quick coupler then the operator can easily drop the attachment and pick it up on a separate set of pins that changes the mounting position of the grab. Just like below: Advantages: More flexibility and control than the mechanical options Can be mounted facing two different directions Only requires 1 auxiliary hydraulic circuit on the machine Cost vs a rotating grapple Ideal for large scale work e.g. loading trucks or burn piles Can be removed easily especially the machine has a quick coupler Considerations Doesn’t offer the control of the rotating versions Can sometimes be awkward to use compared with the rotating version and the machine may have to be moved around more Not as well suited for jobs with tighter spaces Rotating Models Rotation models, also known as rotating grabs or grapples, feature a hydraulic rotator that allows the attachment to swivel independently of the excavator’s arm. This added flexibility makes them ideal for tasks where the ability to rotate the attachment is essential. The rotator is bolted between the grab itself and the excavator mount. The hydraulics to open/close the grab run through the rotator to allow endless 360 degree rotation without any hoses getting tangled etc. The main limiting factor for these attachments in the US market is the need for 2 separate auxiliary hydraulic functions. Most machines in the US only come equipped from the factory with 1 hydraulic circuit for operating a thumb. Machines can be ordered from the factory (at an additional cost) with two circuits and some newer machine makes include 2 as standard (Takeuchi). In cases where the excavator lacks the necessary dual hydraulic circuits, there are electrical kits available that enable the switching of hydraulic functions between opening/closing and rotating the grab or grapple. These kits provide a viable solution for excavator owners looking to utilize rotation attachments without extensive hydraulic modifications. Advantages: Ability to pick up, rotate, and place materials precisely without moving the entire excavator. Improved efficiency when working in confined spaces or

Comparing Tree Shear Attachments for Excavators and Skid Steers: Single Arm vs. Double Arm Designs

Introduction Tree shear attachments have revolutionized the forestry industry, allowing for efficient and precise tree removal. There are many types of tree shear attachments designed for excavators and skid steers, each offering unique features and advantages. In this article, we will delve into the key differences between these attachments including the single arm vs double arm and additionally the distinction between tree shears that can both cut and hold and those specifically designed for cutting only. Tree Shear Basics A tree shear attachment is a powerful tool used in the forestry industry to cut down trees efficiently and safely. It consists of a large, powerful hydraulic cylinder and sharp cutting blades designed to handle various tree sizes. Equipped with robust cutting mechanisms, tree shear attachments can effectively cut trees ranging from 1 inch up to 18 inches in diameter. The hydraulic cylinders generate the necessary force to operate the cutting blades or pull the tree into a fixed blade. These attachments are specifically engineered to withstand the demanding tasks of tree removal, providing operators with a reliable and efficient solution for their forestry operations. Skid Steer vs Excavator Tree Shears It is important to note the fundamental differences between tree shears designed for skid steers and those tailored for excavators. Both versions are specifically engineered to work with their respective machines, optimizing performance and compatibility. Fundamentally skid steers don’t have the reach and flexibility of an excavator. Therefore what you tend to notice is that skid steer tree shears are more designed towards being able to cut the largest tree diameter possible. And since skid steers are most common in the US market, they are less focused on precision and more on cutting capacity. Excavator tree shears tend to be more catered toward the European market where work is carried out more precisely and in tighter areas due to land construction. What you’ll notice is that most excavator versions have the ability to cut and hold trees to enhance the precision and be able to clear land around houses etc. We will explain this in greater detail later in the article. Skid Steer Mounted Tree Shears Skid steer tree shears are designed to attach to the universal quick attach system for skid steers, which are known for their maneuverability and versatility in various applications. Skid steer attachments come in a wide range of options, catering to diverse needs and budgets. The spectrum spans from basic and cost-effective shears to heavy-duty, high-end models. This variety allows operators to choose a skid steer tree shear that aligns with their specific requirements, whether they are clearing smaller trees and brush or tackling more demanding forestry projects. Skid steer tree shears range anywhere in price from around $4k to over $20k. Of course there are many reasons for this huge price difference. A basic skid steer tree shear will consist of a skid steer mounting plate, a hydraulic cylinder that moves the blade into a fixed serrated edge. The cheaper models will be fixed horizontally to cut trees down at the ground and let them fall over. See a basic tree shear model below: Rotating Versions One step up from this base model would usually include some range of rotation for the shear. This lets the operator change the angle from left to right for trimming branches or cutting a felled tree on the ground. The cheapest option would be for a manual rotation that the operator would have to get out of the machine and change the mounting position from horizontal to vertical. Other shears have another hydraulic cylinder that rotates the shear from within the machine. Control Systems for Hydraulic Rotations Being able to rotate the tree shear hydraulically without having to leave the machine saves a lot of time and energy on the job site. However this requires a way to switch the hydraulic oil flow from the cutting cylinder to the rotation cylinder. This requires a simple control system with a solenoid valve to switch functions. This means that the operator wouldn’t be able to do both functions at the same time. Excavator Tree Shears As mentioned before the excavator tree shears are often vastly different to the skid steer versions. Although there are some versions in the market that can be used on both skid steers and excavators. One main difference that we notice on the excavator tree shears is the ability to cut and hold. Some of the higher end skid steers do have this ability but most don’t. Because of this difference in design, what we notice is that most excavator tree shears have a fixed blade and an arm (or two) that pulls the tree into that blade to cut it. Rather than the actual blade moving itself, which we tend to see on the skid steer version. This is to enable the operator to hold the tree with the arms once the tree has been cut. This is vital because then the operator can place the tree exactly where they want and prevent it from falling on any surrounding objects or people. This is very important in smaller countries that are often working in much tighter areas and is perfect for urban job sites. Also because of the excavators long reach, this enables the operator to precisely trim tree branches too, which is another benefit over a skid steer mounted shear. Like the skid steer version there is a rotating version available for most excavator tree shears. This usually uses a worm drive gear that lets the operator rotate the shear endlessly for a full 360 degrees. Worm drives give a strong holding torque over a hydraulic cylinder, meaning that the shear will hold at any cutting angle. Double Arm Designs Double arm tree shear attachments for excavators are equipped with two hydraulic arms. These arms work in tandem to pull the tree into a blade for cutting. This design provides enhanced stability and control during tree cutting operations. Double arm shears are highly

NEW PRODUCT: Excavator Flail Mowers for Excavators up to 7 tons!

An excavator flail attachment is a type of heavy-duty machinery that is commonly used in construction, land clearing, and forestry work. It is an attachment that can be mounted on the excavator, and it is designed to cut down and mulch vegetation, such as trees, bushes, and other plants, as well as to clear debris and other materials. Typically lighter and cheaper than a full size forestry mulcher – they are more designed towards brush and grass clearing making it ideal on a mini excavator. The introduction of the excavator flail mowers adds to our range of attachments suited for the forestry and land clearing industry. Made by Cangini Benne in Italy (a Kinshofer company) these flails are designed to be light and nimble on the machine to allow maximum flexibility. But also heavy duty and well built to last and tackle tough jobs. Current Forestry Range from The Attachment Company: Auger Torque Hedge Trimmer – Skid Steers & Excavators – Trims branches up to 1.5” Cangini Flail Mower/Mulcher – Skid Steers & Excavators – mulcher material up to 2.5-3” diameter Sidney Attachments TBL1000 Tree Shear – Skid Steers & Excavators – Cuts trees up to 10” diameter Sidney Attachments HTC & HTC Plus – Skid Steers & Excavators – Cuts Trees up to 16” diameter Auger Torque Stump Planer – Skid Steers & Excavators – Small to Medium Size Stump Removal Solesbee’s Stump Puller – Large Excavators – Large Scale Stump Removal Flail Mower/Mulcher Overview Flail attachments use a hydraulic motor and a barrel – usually belt driven – equipped with knives or hammer type tools to spin and cut down vegetation and grass. They are designed to tackle material smaller than a mulcher with teeth that is designed to mulch full trees. Some specific applications for an excavator flail attachment include: Land clearing: An excavator flail attachment is useful for clearing large areas of land quickly and efficiently. It can clear brush, trees, and other vegetation, making it ideal for preparing land for construction or agricultural purposes. Forestry work: An excavator flail attachment is often used in forestry work to clear areas for logging, create firebreaks, and remove underbrush. Roadside maintenance: An excavator flail attachment is ideal for maintaining roadside areas, such as clearing brush and trees from the roadside, removing rocks and other debris, and trimming back overgrown vegetation. Pipeline and powerline maintenance: An excavator flail attachment is often used for pipeline and powerline maintenance work. It can clear vegetation and other obstacles from the path of the pipeline or powerline, making it easier to access and maintain. Flail Attachment Models Currently we offer the two smallest models from Cangini in the following widths: TC1 – Excavators up to 3.5 tons Available 24″, 30″ and 40″ wide TC2 – Excavators up to 7 tons Available 30″, 40″ and 48″ wide Further specifications can be found on our website here – https://attachmentco.com/product/excavator-flail-mower/ Mounting Options As with all of our attachments, we will custom build the mount to suit your machine and/or quick coupler. This includes typical double pin setups, John Deere Wedge Lock, Kubota Style Quick Couplers, Bobcat X Change Couplers & more. Contact us if you have any questions about mounting the attachment to your machine. Features One unique feature that is offered for the Cangini brand is the 4 bar floating linkage system. The floating system enables the mower to follow the contour of the ground with the machine staying at the same level. Overall, an excavator flail attachment is a versatile and powerful tool that can be used in a wide variety of applications. It is especially useful for clearing vegetation and debris from large areas quickly and efficiently. Contact us for more information regarding a flail attachment for your excavator or skid steer.

An Extensive Guide to Excavator Mounting Options

Contents Single Pin Double Pin / Cradles for Augers Dedicated Quick Connect – Kubota, John Deere, Bobcat, Wain Roy S Type – Tiltrotators Fully Hydraulic Coupler Systems Single Pin Mounts The cheapest and most simple way to mount an attachment to your excavator is through a single pin hitch that pins through the stick of the machine. This would replace your bucket main pin and allow the attachment to swing freely from the machine. Of course, not all attachments can be mounted through 1 pin, the most common attachment that would be mounted this way would be an auger attachment. Other attachments like trenchers, shears, grabs etc. must be double pinned in order to change the position of the attachment. Augers mostly just need to hang vertically so the single pin is the fastest, cheapest option. Other attachments that use a single pin system are clamshell buckets for material handlers, demolition grapples for use in scrap yards etc. Most attachments require more flexibility that working in the vertical position all of the time. Double Pin The most conventional system for mounting attachments on excavators is a double pin setup. One main pin through the stick of the machine and a second pin through the H link, lets the operator change the angle of the attachment. Conventionally this would have been the setup on the first excavators that only used buckets. As mentioned earlier most attachments need to be mounted this way to allow more flexibility for the operator. However, what makes this mounting setup more complicated is the variation of pin dimensions across different manufacturers’ makes and models. For example, even for a similar size machine, a John Deere excavator and a Caterpillar excavator will have different pin dimensions. We have an extensive list of machine’s pin dimensions available here. Here is a rough guide of the pin diameters for machines based on weight class (rough guideline): 1.5 to 2.5 tons – 25-30mm 2.5 to 3.5 tons – 30-40mm 3 to 5 tons – 40-50mm 5 to 10 tons – 50-60mm 10-15 tons – 60-70mm 15 to 22 tons – 70-80mm 22 to 25 tons – 80-90mm There are a few main pin dimensions that need to be verified to build a mount for an attachment to suit: Pin Diameter Dipper/Stick Width Link Width Pin Center to Center For a pinned attachment for a machine without a quick coupler, we would build the attachment to these dimensions to allow for a good fit to the machine. This would mean that it would be a tight fit around the machine and the pin centers would be what the manufacturer requires to enable full movement of the attachment. From The Attachment Company this would require a short lead time in order to build the attachment mount to suit the OEM pin dimensions. Quick Couplers Quick couplers are an attachment that is fitted to the excavator to allow the operator to easily change between buckets and other attachments. Manual Quick Couplers A manual coupler is manually opened and closed by the operator in order to lock the attachment in place securely. The operator would pick the attachment using the front on, before getting out of the machine to open the coupler and lock in the rear pin. These couplers require the operator to get out of the machine but are a lot faster and easier than manually knocking out the pins of one bucket to put on another. Hydraulic Quick Couplers A Hydraulic coupler uses the same concept but is hydraulically opened and closed meaning that the operator doesn’t have to leave the machine while changing attachments. This makes changing buckets or other tools even faster and easier on the job site, saving time and effort. What does this mean on the attachment side? Quick couplers make it slightly easier on the attachment side for building a mount. The pins can be welded/fixed in order to prevent more movement/slop from having loose pins. However, we can still provide loose pins in case the attachment ever has to be manually pinned on another machine, or the coupler has to come off the machine to be fixed etc. Manual couplers tend to be specific to the excavator and pick up the OEM pin dimensions. The distance in between the ears on the attachment isn’t as crucial as long as it is wide enough for the coupler to drop down and grab the pins. A wider space between the ears or bosses isn’t too bad since the coupler will lock the attachment tight in place. However hydraulic quick couplers usually pick up a range of pin centers and pin diameters on the attachment side. This means that you can usually pick up some attachments that are actually built to suit other machines as long as the dimensions fall in the pick up range of the coupler. And again providing the boss spacing or distance between the ears is wider than the coupler. For this reason, to try and create faster lead times, we have created a universal standard for each pin diameter. This will allow for faster shipping of machines that are manually pinned and also for machines with a hydraulic coupler (since they pick up a range). For a machine with a manual coupler we will still have to build the mount to suit the specific dimensions. We have looked at all the machines with a specific pin diameter and made a standard stick width dimension that suits the machine with the widest stick. For machine’s with a narrower stick, we will provide a shim kit in order to achieve a slim fit. For the pin centers, we have averaged all the pin centers measurements for machine’s with each pin diameter. This means most hydraulic couplers will be able to pick up this center to center measurement. Also manually pinned on attachments will be able to be pinned on normally. The pin center will be slightly different from the OEM dimension, but the difference

Excavator Bucket Pin Size Chart

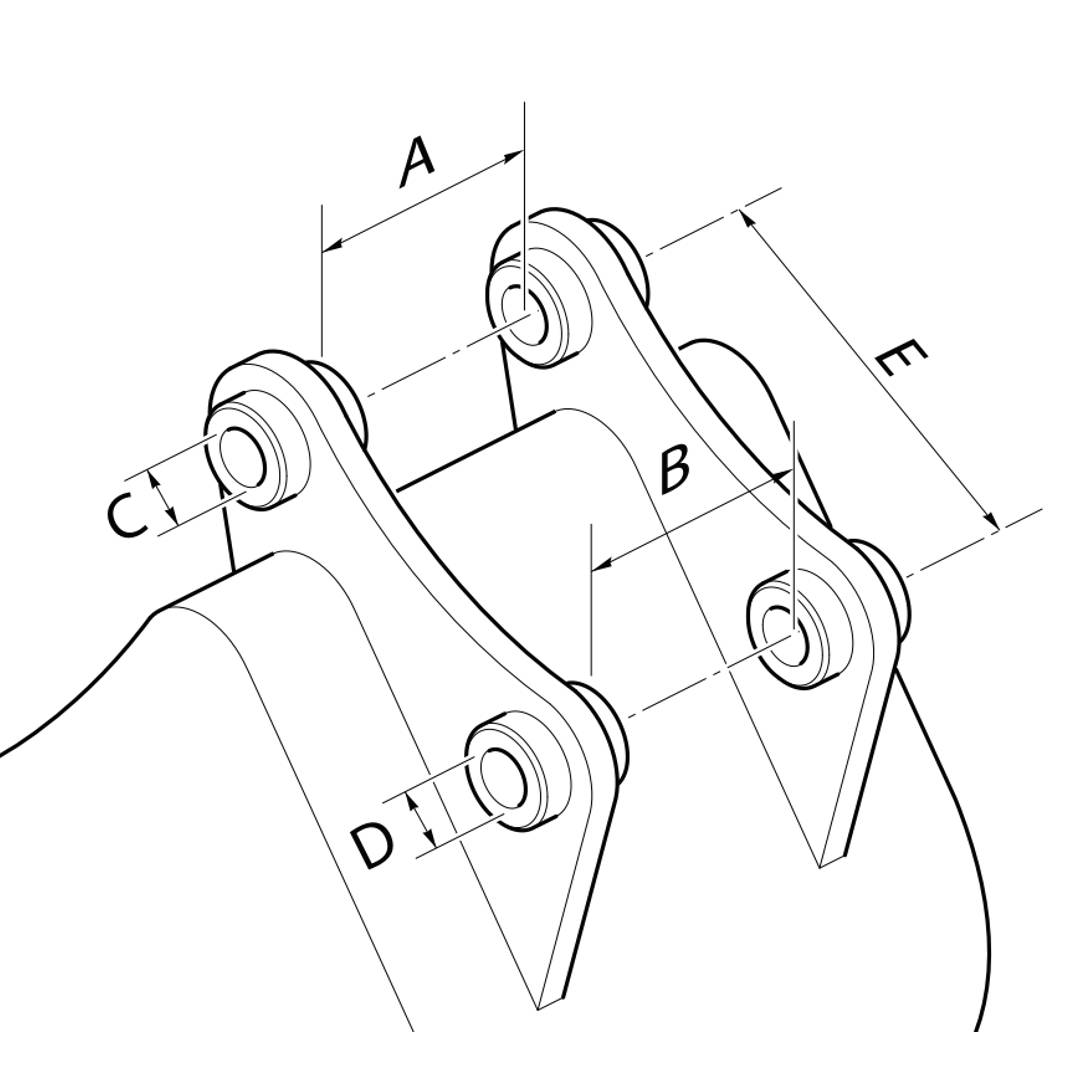

Excavator bucket pin dimensions vary between excavator make and models. This makes it complex to build or fix a mount for an excavator. Most excavators have a double pin configuration with two round pins. The measurements that are needed (shows below) to build a mounting bracket is the pin diameters (C & D), dipper/stick width (A & B) and center to center (E). Download Bucket Pin Dimension Chart! Find Our In Stock Excavator Mounting Brackets Here! Our Extensive Guide to Excavator Mounting Options Here!

Maximizing Your Skid Steer with Trencher Attachments: A Comprehensive Guide

Maximizing Your Skid Steer with Trencher Attachments: A Comprehensive Guide If you own a skid steer, you know just how versatile and indispensable these machines can be. But did you know that you can make your skid steer even more versatile and capable with the right attachments? One attachment that can greatly enhance your skid steer’s capabilities is a trencher attachment. In this blog post, we’ll take a comprehensive look at skid steer trencher attachments and how they can help you tackle a wide range of digging and trenching tasks with ease. What is a Trencher? A trencher attachment is a device that is usually attached to the front end of a skid steer, or onto an excavator to transform it into a trench digging machine. Trencher attachments come in a range of sizes and designs, making them suitable for digging trenches for a variety of applications, including drainage, plumbing, electrical, and landscaping. Types of Trencher Attachments There are several types of trencher attachments available, each designed to meet specific needs and requirements. The two most common trencher types are: Chain Trenchers: These trenchers use a rotating chain with cutting teeth to dig into the ground and create a trench. They are best for digging in soft or loose soil, and are available in different sizes for different trenching depths. These are what you will find on excavators and skid steers. This is what we would traditionally think of as a trencher attachment for a skid steer. There are also older dedicated trencher machines that use the same design and technology. However these can only be used for trencher whereas a skid steer trencher can be swapped out for a lot of other attachments to help with other jobs/tasks. Wheel Trenchers: Wheel trenchers use a wheel with cutting teeth to dig into the ground, creating a trench. These trenchers are best for digging in harder soil and are capable of digging deeper and wider trenches than chain trenchers. Chain Trencher Attachments for Skid Steers & Excavators Trencher attachments for skid steers and excavators use a hydraulic motor and planetary gearbox with a sprocket to drive the chain. The chain engages with the ground and moves the dirt up the chain to the auger. The auger then neatly movies dirt to the side of the trench. There are a variety of chain types of trencher attachments. Mostly what we provide is called a combination chain. The chain has a combination of earth/dirt teeth to move the dirt, and tungsten carbide, shark like, teeth to break up the ground. You can however get a chain that has all of the same teeth. A chain of completely earth teeth would be used in softer ground whereas a complete carbide chain would be used in harder ground. There are other types of trencher chain teeth in the market to deal with harder or more rocky conditions as shown below: Advantages of Skid Steer Trencher Attachments There are many advantages to using skid steer trencher attachments, including: Speed and Efficiency: With a skid steer trencher attachment, you can quickly and efficiently dig trenches, reducing the time and effort required to complete the job. Neatly displacing the dirt to one side of the trench makes it easier and faster to backfill the trench. Accuracy: Trenchers allow the operator to work at a specific depth and width. You can dig an accurate trench at a desired depth and width without effort maintaining the correct depth. Our trenchers have depth control that allows you to vary the digging depth of the trench. For example with our 48” trencher, you can dig at 32”, 40” as well as 48”. Versatility: Skid steer trencher attachments are highly versatile, allowing you to tackle a wide range of digging and trenching tasks with ease. Also since there are many other skid steer attachments on the market, you can easily switch to another attachment to complete another job once you are done trenching. Cost-Effective: Compared to traditional digging methods, using a skid steer trencher attachment can be much more cost-effective, especially for smaller projects. As mentioned a trencher attachment is much cheaper than a dedicated trencher unit. Improved Safety: Trencher attachments allow you to dig trenches from the safety of your skid steer, reducing the risk of injury and improving the overall safety of the job. Purchasing a Trencher Attachment For a Skid Steer Firstly, you will have to determine how deep and wide that you want to dig your trenches. The maximum depth and width that you can dig with your skid steer will be determined by the size and hydraulic flow and pressure of your machine. The most common trencher on the market for skid steers with standard flow hydraulics (anything up to 25-30 GPM) will be able to trench 48” (4 feet) deep. If you have a larger skid steer with flow over 30 GPM you can use a high flow larger trencher unit that can go as deep as 5 feet. Also with a bigger machine you will be able to dig a wider trench at 4 feet compared to a standard unit. Here is the breakdown of the skid steer trenchers that we offer at The Attachment Company: Auger Torque MT Trenchers: Hydraulic Flow from 12 to 27 GPM Auger Torque MT24 Trencher: 24” deep – Maximum 12” Wide Auger Torque MT36 Trencher: 36” deep – Maximum 10” Wide Auger Torque MT48 Trencher: 48” deep – Maximum 8” Wide Digga XD High Flow Trenchers: Hydraulic Flow from 25 to 45 GPM Digga XD High Flow Trencher: 48” deep – Maximum 12” Wide Digga XD High Flow Trencher: 60” deep – Maximum 12” Wide For more information you can visit our website listings here! Installing Your Trencher Onto Your Skid Steer Most trenchers come delivered to you ready to go straight to work. Our trenchers all come with hoses and flat face couplers to connect straight to the machine. It’s just a matter of picking up the unit,

Transform Your Skid Steer Into A Tree-Cutting Forestry Machine With a Tree Shear Attachment

We are happy to add to our range of skid steer attachments with the heavy duty tree shear from Sidney Attachments. Designed and manufactured in the US to the highest standards, the Sidney Tree Shear is one of the best on the market today. The addition of the tree shear range from Sidney Attachments adds to our range of forestry & landscaping products with the likes of the Auger Torque Hedge Trimmer, Stump Planer & Stump Puller attachments. The range of shears help fill a gap in our range that we have had with the ability to cut trees up to 16” in diameter. Current Forestry Range from The Attachment Company: Auger Torque Hedge Trimmer – Skid Steers & Excavators – Trims branches up to 1.5” Sidney Attachments TBL1000 Tree Shear – Skid Steers & Excavators – Cuts trees up to 10” diameter Sidney Attachments HTC & HTC Plus – Skid Steers & Excavators – Cuts Trees up to 16” diameter Auger Torque Stump Planer – Skid Steers & Excavators – Small to Medium Size Stump Removal Solesbee’s Stump Puller – Large Excavators – Large Scale Stump Removal Tree Shear Overview Are you tired of using outdated and inefficient methods for tree-cutting tasks? Look no further than a tree shear attachment for your skid steer. These attachments offer increased efficiency and versatility, allowing you to tackle any tree-cutting job with ease. Tree shears use a large heavy duty hydraulic cylinder and sharp cutting edge to shear through trees. This allows for cutting flush with the ground and fast, efficient tree removal. The Sidney design moves the cutting edge of the shear to push the tree into the fixed arm of the shear. There are two main types of tree shear attachments available – standard and rotary. The standard option is perfect for straightforward cutting tasks, while the rotation feature offers a 110-degree cutting range, making it ideal for more complex jobs. Sidney Attachments manufacturer 3 types of tree shear attachments that are available to suit both excavators and skid steers. TBL1000 – 10” Cutting Diameter HTC – 14” Cutting Diameter HTC Plus – 16” Cutting Diameter Specifications Model: TBL1000 Rated Capacity: 10″ diameter Weight: 655lbs Blade Cylinder Size: 4″ x 18″ Tilt Cylinder: 3″ x 8″ Solenoid: 12v Blade Material: “T1” Steel Model: HTC14 Rated Capacity: 14″ diameter Weight: 1,280lbs Blade Cylinder Size: 5.5″ x 18″ Tilt Cylinder: 3″ x 8″ Solenoid: 12v Blade Material: “T1” Steel Model: HTC16 Rated Capacity: 16″ diameter Weight: 1,300lbs Blade Cylinder Size: 6″ x 18″ Tilt Cylinder: 3″ x 8″ Solenoid: 12v Blade Material: “T1” Steel Features Cut trunks in a single pass, flush with the ground Hydraulic tilt cylinder rotates up to 110 degrees to move cut trees Major pivot points are machined and greasable for long lasting life Shear is made from 1″ high tensile steel plate The single blade design encourages trees to fall the direction of the blade’s travel Serrated jaw grips tree to allow all power to be applied to the blade Blade Cylinder is rated for 3,000psi operating pressure Single 1-1/4″ blade Comes standard with Universal Skid Steer Attach An extremely simple attachment however the output of a Sidney Tree Shear is unmatched. An optimal design with US build quality, the Sidney range of tree shears are able to tackle most jobs with great efficiency and safety. Another great aspect of tree shear attachments is their compatibility with various skid steer models. This means that no matter what type of skid steer you own, you can easily add a tree shear attachment to increase its functionality. Shears have a relatively low hydraulic flow requirement, meaning they can be fitted to most skid steers without any modification. An operating pressure of 3,000psi is easily obtainable for most machines, too. Frequently Asked Questions What are the benefits of using a tree shear attachment for my skid steer? It offers increased efficiency and versatility in tree-cutting tasks, as well as customizable cutting length and robust construction. It offers increased efficiency and versatility in tree-cutting tasks, as well as customizable cutting length and robust construction. What types of shear attachments are available? Standard and rotary options are available as well as models with a grapple and saw feature. Will a tree shear attachment fit my skid steer model? Most tree shear attachments are designed to be compatible with various skid steer models. Using the universal hook up and usually a wide operating range of hydraulic oil and pressure, means that they can be suited to most skid steers. How do I install a tree shear attachment on my skid steer? The installation process will vary depending on the specific attachment and skid steer model. But it typically involves connecting the attachment to the skid steer’s hydraulic system. For a rotating shear – a control kit will be included that will be fitted into the cab to allow the operator to switch between the cutting function and the rotating function. Meaning that you only need one hydraulic circuit to work the shear fully. How do I maintain my tree shear attachment? Regular maintenance, such as lubricating moving parts and tightening bolts, will help extend the lifespan of the attachment. What are the safety precautions I should take when using a tree shear attachment? Always wear protective equipment, such as safety glasses and hard hats, and follow the manufacturer’s guidelines and safety procedures. Testing out the shear on smaller trees to get comfortable with how the tree will fall and directing the fall away from the machine, is also important. How does the pricing of tree shear attachments compare to other skid steer attachments? Pricing will vary depending on the type and brand of the attachment, but it is generally comparable to other skid steer attachments. Heavy duty models, built in the US, will tend to cost a little more than some skid steer attachments, but the quality and support is unmatched compared to cheaper, simpler models. Now available from The Attachment Company

Ultimate Guide to Auger Attachments for Skid Steers & Excavators

At The Attachment Company we have been providing auger setups to our customers longer than any other attachments in our range. We have experience in all sizes of auger setups for mini skid steers up to 30 ton excavators. A simple concept, however there are often many auger options for the exact same machine, depending on the job at hand, budget and many other variables. We have created the ultimate auger guide to try and answer as many questions as possible and cover all the bases when it comes to auger setups for both skid steers and excavators. As always if you have any questions that we have missed you can post a comment underneath or contact us here. Contents What is an auger setup and how does it work? Advantages of using an auger attachment Why it is important to select the correct auger drive for your machine Hydraulic Oil Flow & Pressure Specifications Mounting options for skid steers & excavators Output shaft sizes and auger diameters Auger Bit Types Auger Packages from The Attachment Company What is an auger setup and how does it work? In the construction industry, auger drives are common on job sites of all shapes and sizes from small fence posts to large holes for screw pile foundations. While there are hand held auger units that you can rent from your local Home Depot, and also large dedicated drilling machines, we are just going to focus on the hydraulic auger drives that are suited for skid steers and excavators. To cover the basics, an auger is just a large drill for drilling holes in the ground the same way that you would drill a hole in a wall, for example. Using the hydraulic capabilities of the piece of equipment, hydraulic auger drives were developed using hydraulic motors and planetary gearboxes. A hydraulic motor just takes hydraulic oil flow and pressure inputs to turn an output gear This motor is then matched with a planetary gearbox in order to amplify the torque output. A planetary gearbox is a common gearbox setup that transfers a high speed, low torque input into a low speed, high torque output. Keep in mind that more torque is the name of the game when it comes to drilling holes. For each auger drive size, a gearbox is specifically designed to give the desired output torque and rpm to suit the needs of that specific size of machine. The more gear sets that are added to the gearbox, the more torque we will get as an output, but we lose speed in terms of revolutions per minute. For example, for a smaller machine with a certain hydraulic flow and pressure output, there is a balance between getting enough torque to turn an auger into the ground, but also not losing all of the RPM. We will cover this more later when we look at the specifications of some of our popular auger drive units. See below cutaway for an example of a fully assembled auger drive. On this smaller unit, there is only 1 set of gears in order to keep a good level of output speed as well as amplifying the torque. Underneath the gearbox is the output shaft of the auger drive. This is what is used to connect to the auger bit that will in turn spin into the ground. See a picture of a full setup below: Advantages of using an auger attachment Now that we have covered the basics of the auger setup and how it works, you might be asking yourself why someone might need to spend more money on another attachment when they could just dig a regular hole? The main advantage of using an auger as opposed to regular digging is that you can drill the hole to the exact size that is needed. This limits the amount of backfilling that is needed. For putting 4×4 posts into the ground, it would be impossible to dig a 6” diameter hole with a bucket. An auger setup lets you drill smaller as well as larger holes, deeper and faster than digging. Another main advantage of using an auger setup is speed. Many customers that purchase an auger are drilling hundreds of holes per day for fence posts etc. An auger lets them drill the same size and depth of hole over and over again. Why it is important to select the correct auger drive for your machine All attachments for excavators, skid steers or any type of machinery have various options. When it comes to hydraulic attachments like augers there is often more than one size or option that will work, even on the same machine. It is vital to select the correct model for a number of reasons. Firstly a unit that is not correctly specified, has a much greater chance of breaking down. This is especially true if a unit is undersized for the machine that it is fitted to. A machine with too much hydraulic pressure or oil flow will blow the motor or gearbox seals very quickly after use. Every hydraulic attachment has an operating range for oil pressure and oil flow. We will cover these more in the next section. These are the two main factors when choosing a hydraulic attachment, after the overall weight of the machine. Most manufacturers will design the attachments operating ranges around a weight class of machines. For example our 6000-40 drive unit has the specs below and is designed to work with excavators in the 7-10 ton range. Also an undersized unit has greater chances of breaking or bending auger shafts and flights because it will not be designed to handle the weight of the machine that it’s on. Equally though, an oversized attachment will not work properly or as designed due to the lack of hydraulic pressure or flow. As well as being too large and heavy for the machine. This is why it is important to select the correct size

NEW PRODUCT – Skid Steer Sickle Bar Mower from Auger Torque

For the last few years we have been offering the hedge trimmer from Auger Torque as part of our attachment range for excavators. We are happy to bring to you our new Skid Steer Mounting System for the Auger Torque T150 Hedge Trimmer / Sickle Bar. We have seen an ever growing popularity for our excavator setup and believe that our new skid steer setup fills a large gap in our product range! Affordably turn your skid steer into a landscaping and trimming machine to trim bushes, hedges, long grass and brush. Contents Overview Specifications Hydraulic Angle Mounting System Control System Overview Sickle Bar attachments have been around for a long time, but now are more effective and flexible than ever. Using the hydraulic capabilities of excavators and skid steers, these type of attachments give another use to these machines than just moving dirt. Feedback from our customers indicate that they can increase their workload and take on new jobs with the right attachments on hand. The sickle bar mower attachments for both skid steers and excavators allow for fast, neat and effective trimming of vegetation and bushes. Applications Roadside hedges/bushes Ditch cleaning and maintenance Tree trimming and thinning Golf course maintenance Residential lawn maintenance Brush & long grass trimming Specifications Although we offer one standard length bar, there are other changeable features to our hedge trimmer attachment that allow it to suit a range of mini excavators and skid steers. However, focusing on skid steers for the purpose of this article, we offer the following specifications: Trimmer Bar Motor Size: 100cc Oil Pressure Range: 2176-3191 psi Oil Flow Range: 13.2-18.8 gpm Max. Cutting Diameter: 1.58” Standard Cutting Length: 5ft (60”) Optional Extension Bar: Extra 40” – Total of 8ft Dimensions (h x w x l): 7.99” x 10.61” x 60.5” Weight: 152lbs Extension Bar Cutting Length: 40” (Combined Cutting Length: 100“) Max. Cutting Diameter: 1.58” Dimensions (h x w x l): 4.65” x 8.86” x 46.93“ Weight: 57.3 lbs Hydraulic Angle Mounting System After having great success with the simpler excavator mounted hedge trimmer attachment, it is the perfect time to launch the new skid steer mounting system. Mounting this style of trimming attachment to a skid steer loader does have benefits, however it does not offer the flexibility of the excavator without an innovative mounting system. Step in the hydraulically adjustable angle mount for skid steer loaders. Using a heavy duty hydraulic cylinder and an electric solenoid configuration, the trimmer can sit outside the width of the skid steer and the cutting angle can be easily changed without leaving the machine. The mounting configuration can also be adjusted to sit on either side of the machine. Control System Each attachment is supplied with a standalone control box that allows us to bypass the specific electrical differences between the skid steer manufacturers. A control box is mounted in the cab that only needs to be connected to a 12V power supply. This box operates the solenoid valve on the mounting frame to switch between operating the bar and changing the angle. As with all products offered by The Attachment Company, we stand behind the build quality and robustness of each attachment but also carry spare parts to get you back up and running as soon as possible. For the hedge trimmer attachment, specifically, we offer the standard Auger Torque warranty of 3 years on the hydraulic motor and a 2 year warranty on all other components. If you have any issues beyond that time frame we are always open to working with you to get the problem resolved in a cost friendly manner. If the attachment doesn’t meet your expectations when it arrives, we will return the product and provide you with a full refund. If you have any questions regarding this attachment or anything else offered in our product range, you can contact us on (941) 212-0037 or [email protected]. Skid Steer Sickle Mower / Sickle Bar from Auger Torque listing! Thank you for reading! The Attachment Company LLC Add to cart Hedge Trimmer Extension Bar – 40″ Long Rated 0 out of 5 $1,095.00 Select options Skid Steer Sickle Bar Mower – Auger Torque T150 Rated 0 out of 5 $7,685.00 – $8,650.00

Complete Guide to Excavator Thumbs

Thumbs are one of the most popular attachments for excavators in the US market. Many machines now come straight from the factory with base plates for thumbs already on the machine, or some with a full thumbs setup installed. A thumb attachment on your excavator turns your machine into a grapple/material handler instead of just a digging tool. The concept is simple and often more affordable than a dedicated grab or grapple attachment. Contents What is an Excavator Thumb? How Does a Thumb Work? Applications Different Thumb Designs Thumb Installation Other Attachment Options The Attachment Company Thumbs Conclusion What is an Excavator Thumb? In principle, an excavator thumb attachment is another lever that can be used in combination with the excavator’s bucket in order to pick up material like branches, brush, rocks etc. Working with a standard digging bucket leaves you slightly limited when it comes to being able to easily pick up and move objects or stacks of objects on the jobsite. What makes a thumb valuable is its simple design and concept, affordability and ease of use. When stored in the upright position it is completely out of the way and doesn’t stop the operator from digging as usual. How Does a Thumb Work? The most common thumb setup is a hydraulic thumb, or to be more specific a main pin hydraulic thumb, which is probably the most popular setup overall. We will cover all of the other thumb variations that are available later in this article. For now we will focus on a typical hydraulic thumb setup and how it works. As mentioned above, a thumb is another lever that lets you pick up material when used with the bucket. Above is a main pin hydraulic thumb. You can see that the pivot point of the thumb is through the main bucket pin that goes through the excavator’s stick. This is the most common setup as it requires the least amount of installation because you are utilizing the main pin as the pivot. However, this is not the only way of setting up a thumb. This main pin hydraulic thumb uses a hydraulic cylinder that is supplied with the thumb to open and close the thumb. The cylinder pins onto the thumb and also to a base plate that is welded on the stick of the machine. This allows the operator to work in different positions depending on how stretched out, or close to the machine they are working. Again, this is not the only way of operating a thumb as the traditional thumbs were what are referred to as manual thumbs, that are fixed in position. Only using the rotational of the bucket to hold against the thumb. However, this offers very little flexibility. At The Attachment Company we have since stopped offering manual thumbs as we believe that the price difference between a manual and hydraulic thumb is worth every penny, and strongly advise the hydraulic option. Applications What makes thumbs so popular is the range of applications that they can be used for and not being a dedicated attachment for one job. When not in use, the thumb can easily be stored out of the way, in the upright position. Common thumb applications: General land clearing: moving brush, trees, logs etc. Demolition – moving concrete waste etc. Stump removal: works well when used in combination with our stump puller Different Thumb Designs Earlier we covered the old style manual thumbs and the most popular main pin thumbs. However, let’s cover the other popular setups before going any further. Hydraulic Quick Coupler Thumb A hydraulic quick coupler thumb (or coupler thumb) works the same as a main pin setup, still mounting through the stick of the machine, but through the coupler, instead of the bucket. This means that you can change between buckets easily, and the thumb stays on the machine. Something to bear in mind when ordering a standard main pin thumb, is the extra work that will be needed to change between buckets. The main difference between a coupler thumb and a standard thumb is the length. To account for the extra height of the quick coupler, the thumb must be longer in order to properly mesh with the bucket’s cutting edge. Hydraulic Stick Mounted Thumb Another popular thumb design is a hydraulic stick mounted thumb. This style is completely independent of any coupler’s or bucket’s by being mounted completely on the excavator. Stick mounted thumbs require more welding when being installed as there has to be two pivot points welded to the machine. Most stick mounted thumbs that we supply come with a large single piece base plate that is welded to the stick. See below. Progressive Link Thumb Perhaps the latest thumb design is the progressive link thumb. This setup uses an extra link in between the hydraulic cylinder and the thumb in order to achieve more rotation. Being able to rotate the thumb further, means that you can work closer to the cab with the stick more upright and still meet the bucket’s cutting edge. In most cases the link is cut out of very thick metal plates to withstand the loads that can be put upon the thumb. Some manufacturers even use a cast link to achieve the strength needed. How To Install A Hydraulic Thumb On An Excavator? Since there are a few different thumb designs, they are all installed slightly differently, however the principle is going to be the same across the board. We recommend having your thumb installed by an experienced excavator dealer/mechanic. In the US, most machines now come with a hydraulic thumb from the factory. If not, they often have a cylinder base plate already mounted on the excavator so there will be no need to weld the base plate yourself. However, when ordering a thumb from any manufacturer, make them aware if your machine already has a thumb base plate installed, as they will have to provide a thumb cylinder that matches