Skid Steer Log Splitter Package Deal

Log Splitter for Standard Flow Skid Steers up to 30GPM & High Flow Skid Steers up to 40GPM!

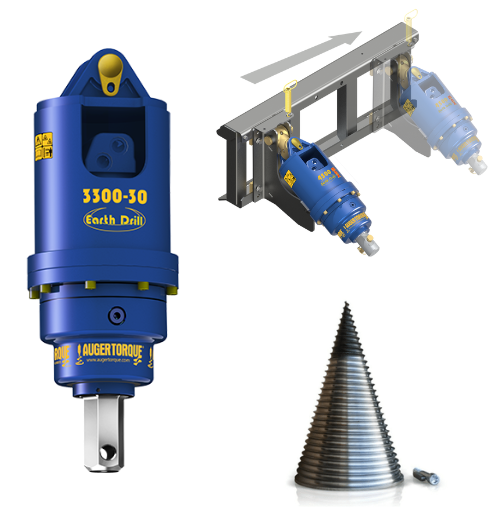

This package deal comes with hydraulic drive, skid steer mount, hoses & couplers, our log splitter auger cone & replacement tip!

Our Splitter Package gives you the best deal on the market for a log splitter setup. If you have a special attachment inquiry or are unsure of your machine’s compatibility with a particular attachment, please do not hesitate to contact us on (941) 212-0037.

Other attachments are also available to work with this auger setup like stump planers & auger bits.